Researchers at USP’s São Carlos School of Engineering (EESC) developed a film made of silicon that is a thousand times thinner than a human hair and could work as a photographic lens, similar to those in smartphone cameras. The unprecedented technology allows the user to see images in up to 180 degrees, the same angle provided by the famous fisheye lenses. In the scientific world, this functionality was so far considered impossible to be obtained with entirely flat lenses, such as the one built by EESC. The results of the work generated an article that was published in ACS Photonics, a North-American scientific journal in the Photonics area, the science field dedicated to studying light.

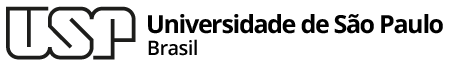

The new lens weighs approximately two micrograms, has around 230 nanometers of thickness, and an area of 3.14 square millimeters. According to the scientists, the expectation is that the material helps face one of the primary challenges in the development of optical devices: manufacturing lenses evermore powerful, yet smaller and smaller. “The most significant benefit of our lens is that it is very thin, so it promises to be cheaper to be produced compared to the conventional ones, which are large and spherical. Since it is a flat surface, it is easier to place it on an integrated circuit, which simplifies the mechanical part of the device”, explains Augusto Martins, author of the study and a doctoral candidate of EESC’s Graduate Program in Electrical Engineering.

Besides the small size, another advantage of the silicon film is that it may act alone inside the cell phone, without the need for incorporating complementary lenses to obtain high-resolution images, as occurs with ordinary cameras. This will contribute to further reducing the size of optical systems and, consequently, of mobile devices. “This is the first lens in the world formed by a single layer capable of generating images that cover the entire field of vision”, states Emiliano R. Martins, one of the advisors of the research and a professor at EESC’s Department of Electrical and Computer Engineering (SEL).

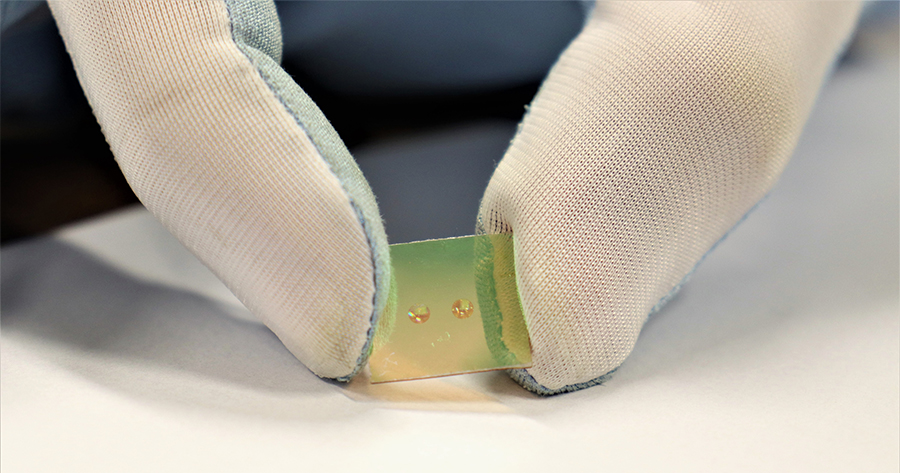

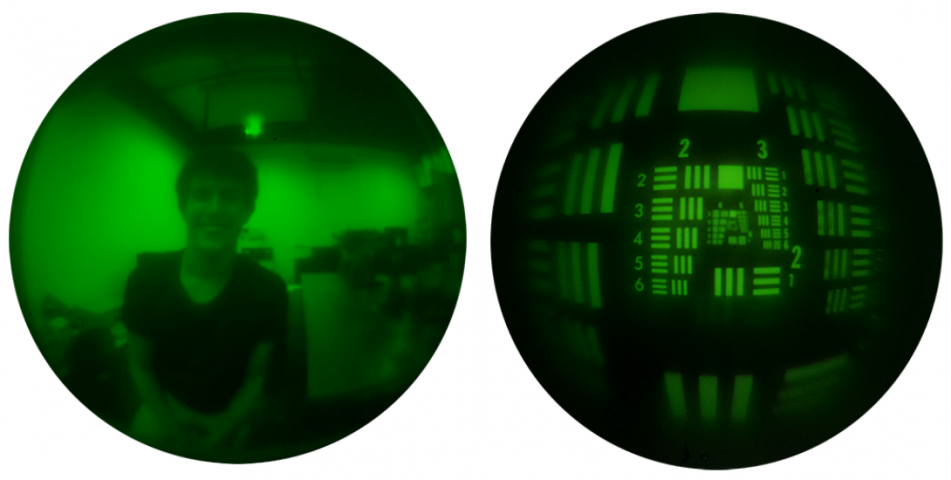

During the research, which was funded by the São Paulo Research Foundation (FAPESP), Augusto Martins built a prototype of a camera with the aid of a 3D printer to test his lens. The results were encouraging. High-resolution images were obtained in the color green, the only color in which the film can operate for now. The idea, according to the researcher, is that, in the next months, the lens is improved so that all colors may be visualized.

To reach the composition of the new lens, the scientists adopted as a starting point traditional lenses themselves and worked with a parameter called the refraction index, which measures how much the speed of light reduces upon shining on a surface – the higher this index is, the lower the propagation speed of light through the material. In computer simulations, they noticed that, as they increased the refraction index of a conventional spherical lens and simultaneously rendered it flatter, its field of vision opened, and the quality of the image improved. At a given moment, when it became 100% flat, its refraction index needed to be infinite, which, in practice, would make it so that light could not propagate through it, something impossible to happen. However, since the silicon film developed by the researchers has physical principles different from those of ordinary lenses, it was able to imitate the optical behavior of the spherical lens with an infinite index, i.e., it began operating as an impossible lens.

Where does the technology come from?

The lens developed by USP is a type of metalens, which is inserted in the concept of metasurface – a set of nanostructures able to control the properties of light. Discovered a few years ago, this technology may be applied to a series of segments besides the production of lenses, such as information security, the manufacturing of computer components, and in entertainment. Last year, for example, Augusto participated in the development of a metasurface capable of generating holograms in three dimensions and with more quality.

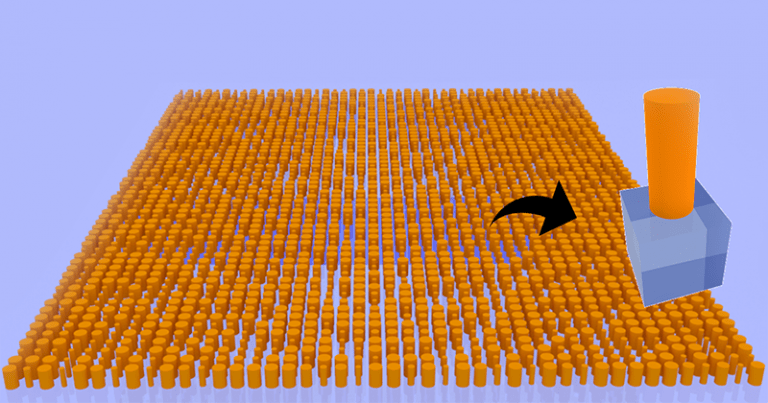

Unlike ordinary lenses, which require a greater thickness to generate sharp images, metalenses microscopic nanoposts inserted into their flat surface capable of “locking in” and focusing the light in the environment, causing images to be projected. It is as if they were highways built not to allow cars (the lights) to leave them. In 2016, Harvard University researchers, in the United States, developed the world’s first metalens capable of taking pictures, but it had a limitation: its field of vision was of only 0.5 degrees, an angle that merely allows seeing what is in front of you.

Now, besides expanding the operation of the metalens to other colors, EESC scientists expect, on the next stages of the study, to increase the film’s efficiency, improve even further its resolution, and apply it to more complex optical systems. For now, there is still no prediction of when the technology may hit the market. The research was also advised by SEL’s professor Ben-Hur Viana Borges, and had the collaboration of researchers from the University of York, in the United Kingdom, and Sun Yat-sen University, in China.

More information: +55 (16) 99727-2257, email comunica.sel@usp.br, at the Communications Advisory of SEL/USP